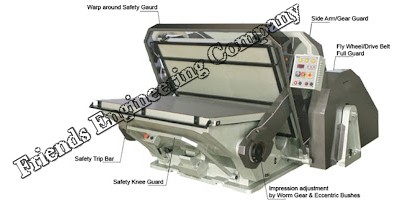

"Friends' Brand Die Punching Machine and Heavy Duty Platen Punching Machine" is intended for die cutting, creasing, and embossing on paper, cardboard, corrugated board, leather, plastic, and pvc, among other materials.

We design our premium Friends complete heavy duty die punching machine with an electro-magnetic clutch and brake for performing all simple and straightforward operations. This Die Punching Machine is capable and designed basically for performing Die-Cutting, Creasing, Punching, and Embossing Job on various merchandise like Paper, Cardboard, Fibre Board, Vinyl, Foam, Rubber, Leather, Masonite, Cork Sheets, affixed Boxes, Advertising Cut out, Jigsaw Puzzles, Labels, and far more.

The multi-functional system provides exceptional output as desired via the client within step with die used within the machine. All below-noted functions permit us to provide a hundred% efficient, correct results. In addition to this, the Platen Die Punching machine that we offer consists of a set of enterprise standards. Our valued customers can obtain the Platen "Die Punching Machine India" from method folks in a variety of sizes based on their requirements.